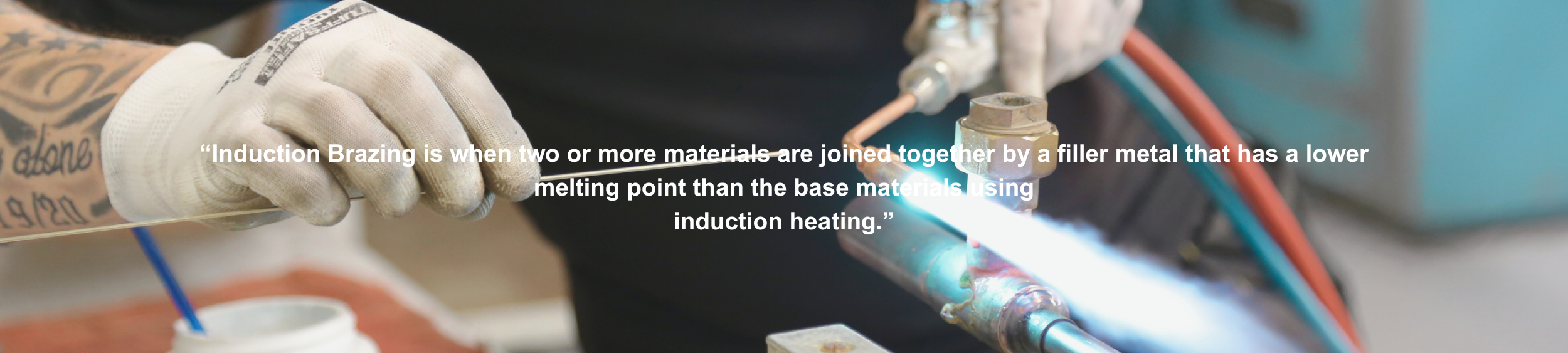

Induction brazing

Induction brazing is a process that joins two or more materials using a filler metal with a lower melting point than the base materials. By applying heat through induction, the joint area is rapidly and precisely heated, resulting in clean, uniform, and leak-proof bonds with minimal thermal impact on surrounding material.

At Mintdale, we use twin-head Safebraze induction systems, featuring low-voltage, operator-safe coils, integrated fume extraction, and PLC-controlled multi-profile heat and power settings. These systems are ideally suited for joining copper to copper and copper to brass with high repeatability.

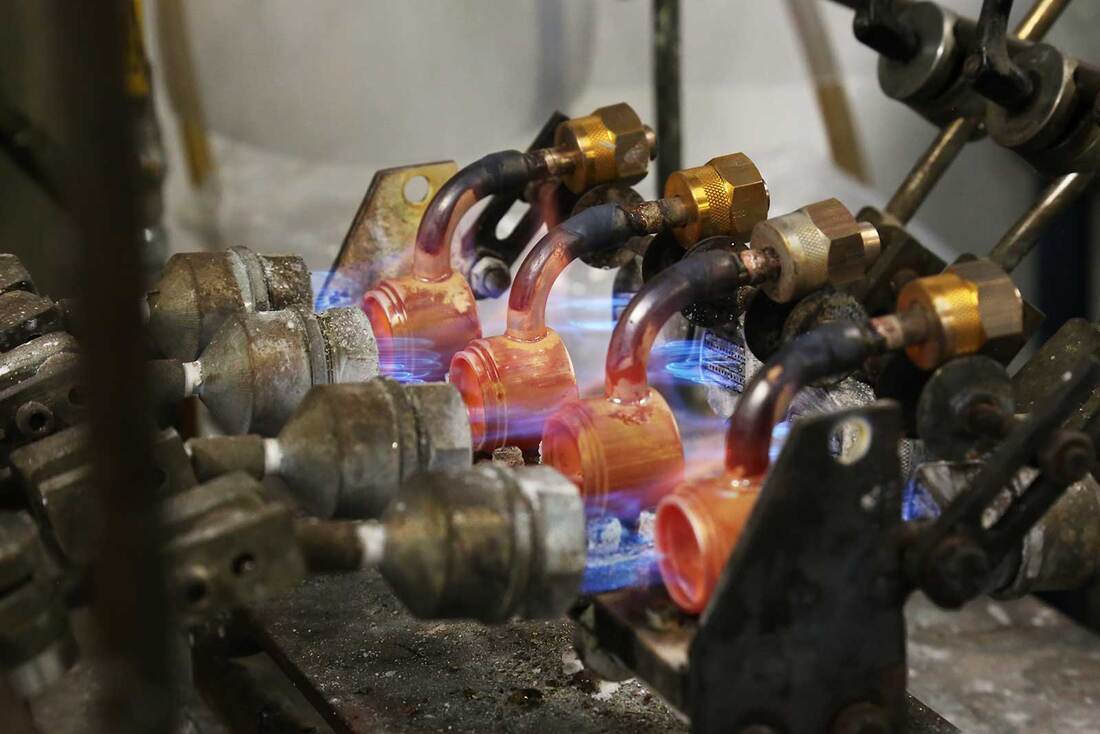

For more complex or larger assemblies, we also offer manual and gas brazing techniques, ensuring flexibility across a range of part sizes and specifications.

Key Capabilities:

-

Copper to copper and copper to brass brazing.

-

Leak-proof joints with uniform heat transfer.

-

Localised heating to reduce heat-affected zones.

-

Safe, repeatable, and efficient production.

-

Gas and hand brazing for technical or large components.

If you have specific brazing requirements or are unsure which method is best suited to your application, our team will be happy to advise.

Find out more about our range of Services & Capabilities: