CNC Turning / Milling

At Mintdale, we use advanced CNC turning, milling, and mill/turn technologies to deliver precise, repeatable, and efficient machining across a wide range of part sizes and complexities. Our multi-axis machines enable one-hit manufacturing to reduce handling, shorten lead times, and maintain tight tolerances throughout production.

CNC Turning

In CNC turning, a rotating bar of material is held in a chuck or specialised clamp, while a cutting tool is fed into the piece to remove material and create the required shape. Our machines operate up to 9 axes, enabling the production of complex components in a single operation.

Most of our CNC turning lathes are bar-fed and capable of 24/7 operation on select materials. For larger or more specialised parts, our chuck-loaded machines are manually operated to pre-set programs.

CNC Turning Capacity:

- Bar-fed: 6 mm to 80 mm diameter / hexagon (down to 1 mm on request).

- Chuck-loaded: up to 250 mm diameter / hexagon.

- Maximum turning length: 250 mm.

CNC Milling

CNC milling involves the use of a rotating cutting tool to work around a stationary workpiece, or internal tooling to bore and tap. Our milling machines also offer multi-axis capabilities, making them ideal for intricate parts and challenging geometries.

CNC Milling Capacity:

- Table size: 900 mm width x 350 mm depth.

- Maximum working height: 500 mm.

- Multi-axis machining for complex components.

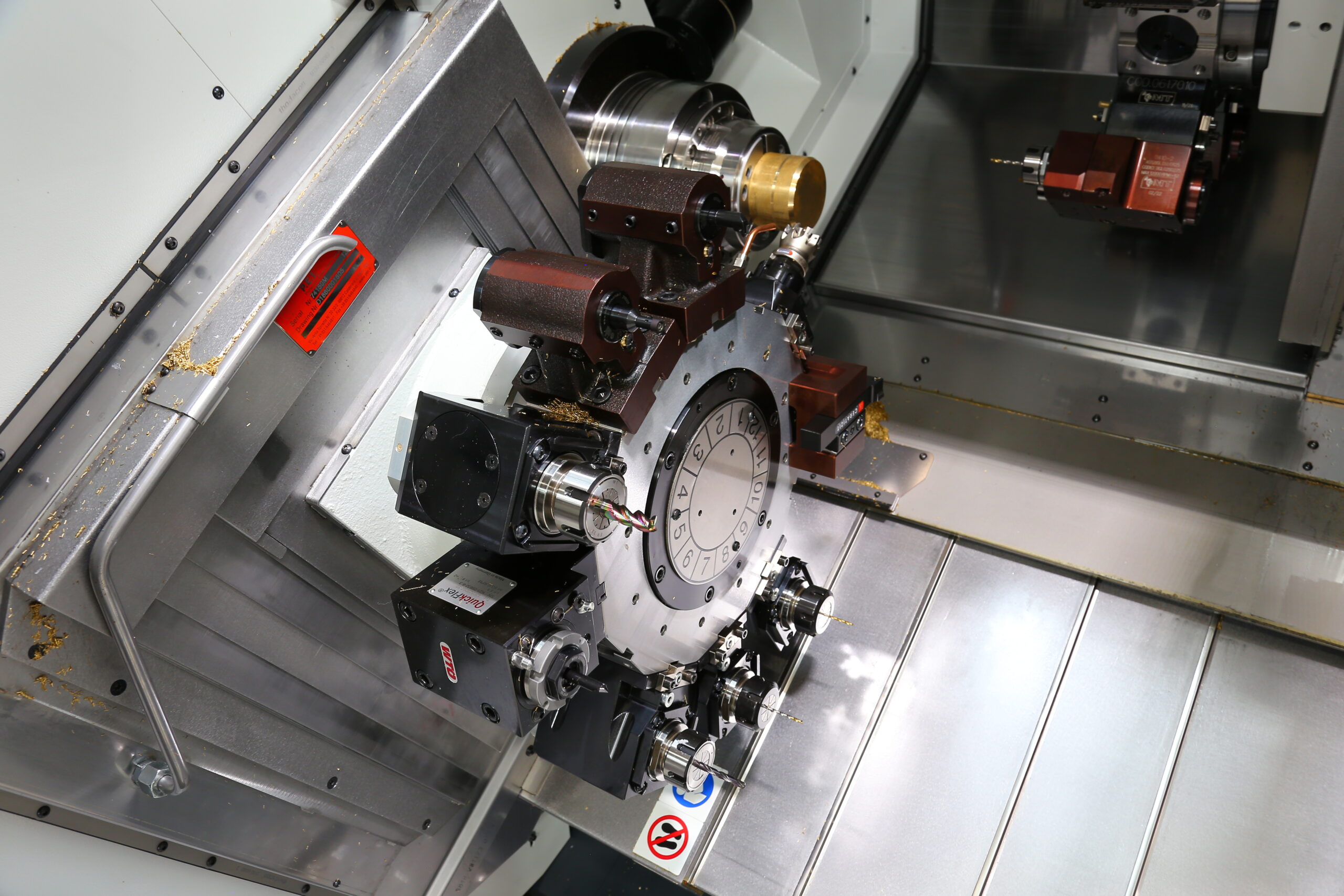

CNC Mill/Turn

Mill/turn machines combine both turning (workpiece rotation) and milling (tool rotation) functions in one highly capable system. These machines allow us to perform multiple operations on a single setup, increasing speed, accuracy, and consistency across complex parts.

Mill/Turn Capacity:

- Diameter range: 6 mm to 80 mm.

- Maximum length: approx. 200 mm.

- One-hit production for milled and turned features.